The Manufacturing Jobs of Today Have Changed Over the Years, and for the Better

Manufacturing jobs are increasingly coming back to the U.S., providing millions of Americans with employment opportunities that have not been available in decades. With the sudden increase in manufacturing jobs after several years on the decline, Americans have grown optimistic that unemployed workers will soon find employment. The issue? Too many people think of a job in manufacturing as a dreary assembly line of workers going through the same motions for eight hours in poor conditions with minimal pay. This is not the reality of what manufacturing jobs are like today.

To encourage more people to take advantage of the return of manufacturing jobs in the U.S., it’s important that we teach children, teenagers, and adults that a career in manufacturing is a strong path with good pay, benefits, and opportunities to grow within the company. Times have changed in the manufacturing industry, and it is time that people’s perception of the career changed as well.

Training Requirements and Safety

Training Requirements and Safety

Then: To have high levels of productivity in the 19th and 20th centuries, companies hired a large workforce to do labor-intensive work. There were very few skillset or experience requirements for factory workers. Because the jobs did not have education requirements, the majority of the workforce was filled with people with little to no education. The lack of training and education combined with poor working conditions led to accidents and work-related injuries.

However, many managers didn’t see the incidents as a problem as they simply needed another body to take the person’s place. Due to the poor conditions and salary rate, employment in the industry was less appealing to people, even for those who were limited in career options.

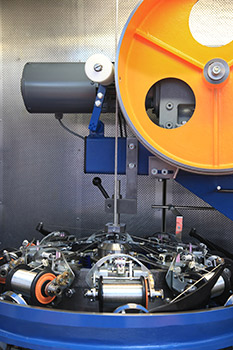

Today: A person without any prior training or skill-building would not be able to work in the manufacturing industry. Along with strict standards for worker safety, automated machinery and new technology have created a higher demand for employees with technical and critical thinking skills. Many career and technical education institutions have also invested in the latest training equipment and software to train their students to ensure maximum safety and efficiency in the workplace.

As a vocational education equipment provider, we have seen the difference in worker safety and company productivity when employees have been trained with the latest learning systems that mirror the factory equipment. The increase in educational efforts has made the career path better in both safety and pay, which makes it an ideal job for people supporting a family.

Technology in Manufacturing

Then: Many people blamed the advancement in technology and machinery for the decline in manufacturing job opportunities. In the post-WWII era, machines and automation made a significant difference in productivity levels. As technology improved, machines proved to be faster and more productive than the average manufacturing worker, and much of the tedious, labor-intensive work was replaced with robotics. In turn, factories saw less of a need for a large labor workforce, causing fewer job opportunities.

Today: Although machine automation has replaced much of the manual labor once necessary in manufacturing plants, technology has not entirely taken over today’s manufacturing workforce. Rather than working by hand, manufacturers are able to use automation and robotics to help complete projects safely and more efficiently. In 2018, America saw the strongest growth in manufacturing employment since 1995, meaning that more manufacturing job opportunities are available, and they involve working with the new technology rather than against it. In turn, newer technology has given people better and more refined career opportunities in manufacturing.

Outsourcing Manufacturing Work to Other Countries

Outsourcing Manufacturing Work to Other Countries

Then: Outsourcing manufacturing work to sweat shops in developing countries has been a highly controversial topic for decades. Throughout the mid-90s and 2000s, there was a trend in American companies of moving their manufacturing jobs to cheaper labor markets in China and India to lower the cost of production. With manufacturing jobs taken out of the American markets, finding employment became increasingly difficult.

Today: Over the past few years, manufacturers have started returning back to U.S. soil. Lower quality products, inconsistent work, delayed shipping, and lingual and cultural miscommunications caused the cost of outsourced manufacturing labor to be more expensive than companies originally expected. According to the Reshoring Initiative in 2016, 50,000 manufacturing jobs left the U.S. while 77,000 jobs returned back home. So as mentioned above, more manufacturing jobs are returning to our country, providing more career opportunities and employment.

The Future of Manufacturing Jobs

Manufacturing jobs today are not the same as they were back then, and the industry will more than likely change again in the future. What we have seen now is that the jobs require workers to have more technical abilities and a critical thinking mindset. However, it is up to the current generation to take advantage of the resources and career opportunities that are provided today to pave the future of manufacturing. By accepting manufacturing jobs as viable careers and encouraging the next generation to consider technical training and development, we can end the stigma of manufacturing and provide people with a better future.

For more information about manufacturing training programs and opportunities, contact Sivad Inc. today!